What are Bowling Lanes Made of: Synthetic & Wood, Which is Better

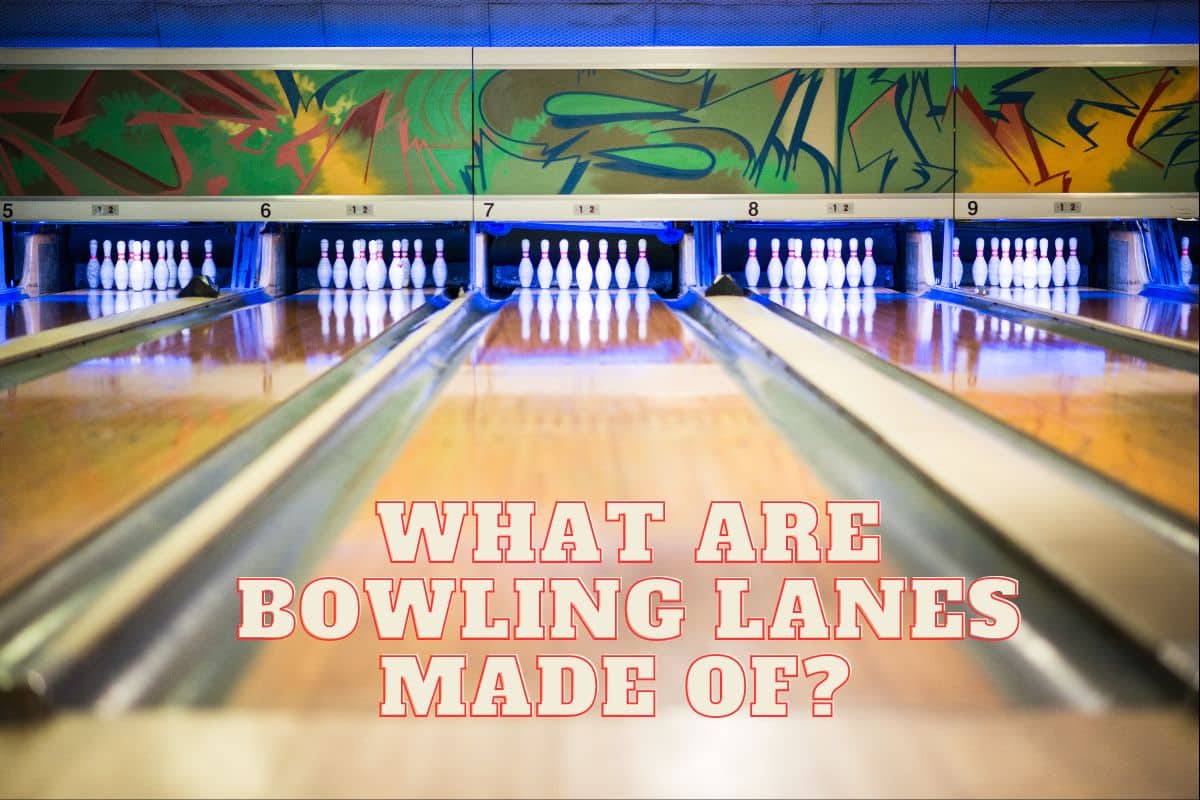

Bowling ball alleys have different material which impacts the performance of a bowler. Beginners in bowling games must try their bowling ability on various bowling lanes to find the lane type ideal for their play style. What are bowling lanes made of? Here is a comparative guide to the materials used to make bowling lane surfaces.

What are bowling lanes made of? A comparative guide. Bowling alleys are mainly made from a blend of wood or synthetic materials to withstand the repeated strikes of bowling balls. The wood combination varies throughout the paths; the part of the lane with the most significant and frequent strikes uses hardwood, and the lane sections with less traffic and fewer strikes have softer wood.

So, we will discuss different bowling alley floors, the ideal thickness of bowling lanes, the surface finish used in bowling lanes, and more.

Different Kinds of Bowling Alley Floors.

Some Bowling lane floors may contain maple, pine, or synthetic wood.

Maple wood bowling lanes. Maple wood is resistant to shock, making it a popular choice for bowling alley flooring. It may often be polished because of the wood's high density and durability. Regarding maple bowling alley flooring, the tongue-and-groove style is the most common, and glue plays a significant role in assembling the flooring.

The areas with the most foot traffic and floor damage have maple flooring installed. This wood can withstand repeated sanding because it is quite durable.

Pinewood bowling lanes. Pinewood is a soft wood mainly used at the center of the bowling path, between the playing surface and where the ball stops. Pine resists shrinkage and rotting, increasing the friction between the lanes and the ball.

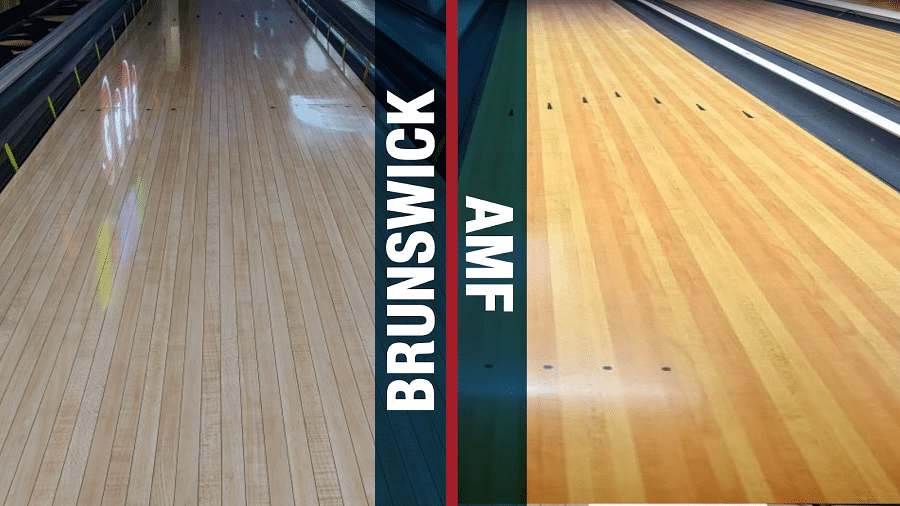

Synthetic bowling lanes. Artificial flooring is more common due to its durability and low maintenance requirements. The artificial flooring in bowling alleys reduces the amount of lane oil needed since it allows for a smoother, more efficient slide for the bowler. This flooring option is cost-effective since it requires little to no upkeep while constantly looking brand new.

Pros of Wooden Bowling Lanes and Synthetic Bowling Lanes.

Here are the pros of both the wooden and synthetic bowling lanes.

Wooden Lanes Pros.

- Hardwood bowling alleys have a softer surface, but the lane will deteriorate and need repair over time.

- Wood is softer than synthetic lanes.

- Bowling balls hook sooner and respond down the lane less strongly than they do on synthetic alleys.

- In contrast to synthetic lanes, wooden lanes absorb oil more readily, resulting in a more rapid pattern change allowing you to make faster adjustments.

Synthetic Lanes Pros.

- Since the synthetic surface is stronger than the bowling ball, synthetic lanes will show less wear and tear than wooden lanes.

- Bowling balls have a more extreme back-end response and slide further down synthetic alleys.

Are Synthetic lanes better Than Wood Lanes?

Now that we have discussed the synthetic and wood lanes, which is better? A plastic ball with a skid motion and no hooking potential will perform best on a wooden bowling lane.

On the other hand, if your bowling ball has more potential to hook and good friction, such as a reacting resin bowling ball, then a synthetic bowling alley will serve you well due to its superior skidding motion in the early stages of the game.

Synthetic lanes are ideal for linear, skidding action and have a limited hooking potential, making them suitable for novice bowlers.

How thick is a Bowling Alley?

Regarding lane thickness, a typical bowling alley is 2 inches thick. This standard is applicable regardless of the material or design of the bowling alley. Sadly, nowadays, there are different types of bowling alleys that are thinner, yet bowling lanes should have the same thickness.

Bowling alleys with a thicker surface resist wear and tear for longer. But still, change them after a certain amount of time since wear and tear might alter the normal movement of the ball.

The Surface Finish Used In Bowling Lanes.

Whether you're bowling on a lane with synthetic material or wood, the bowling surface has a shiny coat of oil. There are two reasons why bowling alleys have a layer of oil patterns.

The primary goal of the oil pattern is to preserve the quality of the bowling alley floor. The oil layer prevents the bowling ball from damaging the lane's surface.

The second purpose is to add complexity and improve the bowler's experience. This smoothness introduces hooks and spins into the bowling alley, challenging even a short ball toss.

Dimensions of a Bowling Alley.

The typical bowling alley is sixty feet long and forty-two inches wide. A 12-ft long surface along the bowling alley is just in front of the foul line.

A foul line is at the far end of the court, and if you cross it while shooting, you'll be called for a foul and lose any potential points you may have earned. There is also a distance of 12 feet between the foul line area and the aiming arrows. The alley stops at the bottom of the lowest remaining pin.

Components of a Bowling Alley.

In general, a bowling alley consists of these parts:

- The area of the approach. When bowling, this is the spot near the foul line where the bowler stands to get set.

- The 39 wooden lanes on the court are all uniform in width.

- Directional arrows for the lanes. Indicators are on the alley to assist the bowler in aiming at the pins.

- Indented passageways on both sides of the lane to accommodate the bowling pins.

- The foul line. Bowlers should stay behind the foul line, drawn at the beginning of the lane.

- The pins deck. The area at the end of a bowling alley where the pins are stored.

Conclusion

The three bowling alley surfaces are the pine wood lane, maple wood, and synthetic alley. The type of ball you bowl with and your play style are the key factors determining the ideal bowling alley surface for you. Moreover, the bowling surface is well-oiled to prevent the ball from damaging the surface from the strikes and make the game more complex, improving your skill set.

![Bowling Gloves [All You Need to Know]](https://www.bowlingknowledge.com/wp-content/uploads/2023/02/Bowling-Gloves-768x512.jpg)

![How Long Does a Game of Bowling Take? [Different Bowlers]](https://www.bowlingknowledge.com/wp-content/uploads/2023/03/How-Long-Does-A-Bowling-Game-Take-768x512.jpg)